What is a patient bed?

A patient bed, often referred to as a hospital bed, is specifically designed for patients in medical settings. These beds come in various types, including bariatric patient beds for larger individuals, and feature adjustable positions to enhance comfort and facilitate patient care. Key specifications like patient bed dimensions and price vary widely, impacting choices for hospitals looking to buy patient beds. Side rails are commonly included to ensure patient safety, while patient bed tables provide convenient surfaces for meals or medical equipment.

When considering the positioning of patients in bed, hospital staff must evaluate bed positions for patients, ensuring optimal comfort and accessibility for activities like transferring a patient from bed to wheelchair. The price of patient beds can differ significantly, depending on features and quality, affecting the overall hospital bed cost. Facilities often seek reliable brands, such as Stryker, known for durable and innovative patient beds that enhance care for patients in a hospital bed. Overall, understanding the diverse options available for patient beds can significantly improve the quality of care provided to individuals in medical environments.

Patient bed By Features

Patient beds feature adjustable positions, durable materials, side rails for safety, and integrated functions like patient positioning and mobility support.

Experience adjustable comfort and safety with our premium hospital bed.

Effortlessly adjust height and position with our electric patient bed.

Designed for critical care, our ICU bed supports advanced patient monitoring.

This manual bed offers easy adjustments for the back and legs, enhancing caregiver convenience and patient comfort.

Our therapeutic bed offers multiple adjustment options to ensure optimal comfort.

Enhance patient care with our smart bed featuring integrated health monitoring.

Designed for accessibility, our high-low bed makes patient care easier.

Incorporating modern technology for real-time health monitoring and data feedback.

Patient bed production equipment

The materials used in patient beds primarily consist of high-strength steel, premium plastics, and comfortable mattresses, ensuring durability, safety, and optimal comfort for patients in medical settings.

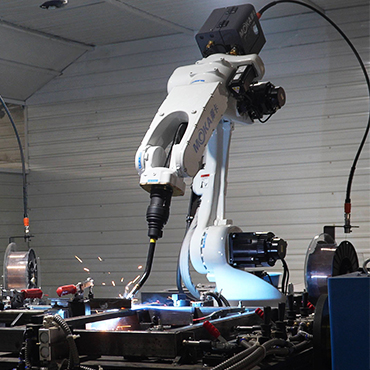

Patient beds utilize welding to connect the bed frame, ensuring structural integrity and a secure connection for durability.

Patient beds and guardrails undergo a spray coating process to prevent rust and maintain a pristine appearance.

The bedside injection molding machine is used to produce bedside. You only need to make a good bedside mold and put in ABS material to blow mold it.

Patient bed punching machine is used for precise punching, facilitating bed frame assembly and adjustment, improving production efficiency and product quality, ensuring the safety and comfort of hospital beds, and meeting medical needs.

The Patient bed assembly process includes the connection of the frame, support and electrical components to ensure that each part fits tightly. This process ensures the stability, safety and functionality of the bed to meet the needs of the medical environment.

Patient bed quality inspection

1. Incoming material inspection: The focus is on the quality inspection of incoming materials, because materials are the basis of quality. The working direction of incoming material inspection is to change from passive inspection to active control.

2. Production process inspection: The focus of production process inspection is the quality inspection after each process is completed. Verify whether the batch of semi-finished products can enter the next process.

3. Finished product quality inspection: Finished product quality inspection is to check the appearance and size of the finished product and deal with unqualified products. Before entering the packaging or storage system, ensure that all goods are qualified

4. Pre-shipment inspection: We will also conduct shipment quality inspection before shipment, and check the product quality, quantity and function.

5. Packaging inspection: We will inspect the packaging again before shipment.

Grace Medical’s patient beds have significant selling points in material selection:

High-strength metal frame: Made of high-quality stainless steel to ensure the bed is sturdy and durable, and anti-corrosion, making it suitable for long-term use.

Antibacterial ABS plastic: The bedside and guardrail parts are made of antibacterial ABS material, which is easy to clean, helps maintain hygiene and reduces the risk of infection.

Comfortable foam theme: High-density foam provides good support, reduces the occurrence of pressure and improves patient comfort.

Environmentally friendly materials: All materials comply with international environmental standards, are safe and harmless, and pay attention to the health of patients.

Functional electric adjustment: The electric function adjusts the bed position according to the nursing staff, improves nursing efficiency, and adapts to the needs of different patients.

These points ensure that Grace Medical’s hospital beds meet the high standards of the medical sales industry in terms of quality, comfort and functionality.

Hospital bed applications

Patient beds play a crucial role in patient care, whether in a hospital or at home. They are designed for comfort and functionality, featuring adjustable heights and positioning capabilities. Hospital bed rentals are available for those needing temporary solutions, with options for hospital beds for home or hospital beds for the elderly. Various types are offered, including electric models like Hill-Rom hospital beds, which enhance mobility and safety. Accessories such as hospital bed mattresses and hospital bed sheets ensure hygiene and comfort. For those looking to rent a hospital bed near me, numerous services provide easy access to quality beds tailored to individual needs.

Company advantages

Our factory is located in Hengshui City, Hebei Province, China. Hebei is a steel production area, so we have a cost advantage. We are very close to Tianjin Port and the transportation cost is relatively low. We can provide customers with better prices.

Grace Medical, Our R&D team actively launches new products every year to meet the changing market needs and has rich experience in OEM services.Since 2018, we have established cooperation with Korean factories and have obtained 100 technical patents and 32 quality certifications, including ISO 9001/13485/14001/18001, European CE, US FDA, Russian Federation registration and Brazilian ANVISA, etc.

We provide you with a full range of after-sales services from purchase to use. We will introduce you to the detailed functions of the product when purchasing. After delivery, we will send you a delivery notice so that you can arrange a time to pick up the goods in advance. After receiving the goods, you will send a satisfaction survey form so that you can submit your request to us. Suggestions; if there is a problem, we will reply within 24 hours and propose a solution within 48 hours.

1. If quality problems occur within one year, we will guide you in repairing them free of charge and provide spare parts that need to be replaced free of charge. If it cannot be repaired, we can arrange to replace it with a new one for you. Guaranteed you have no worries.

2. After one year, if a problem occurs within five years, the customer will be instructed to repair it free of charge, and the consumable parts that need to be replaced will be provided at cost price. If it cannot be repaired due to improper use by the customer, it can be replaced with a new one at a discount of 10% of the current price.

3. Guarantee the supply of spare parts within ten years. Even if the old model is discontinued, we will reserve spare parts or drawings to ensure that the wearing parts of the product you purchased can be replaced. Extend product service life and save social resources.

During the packaging process of the patient bed, we will ensure that all accessories are complete and qualified, package them as a whole or individually according to the order requirements, use bubble wrap to protect them from bumps, and use thickened boxes to prevent damage. At the same time, we will remind the shipping master to handle it with care to ensure that each order reaches the customer safely.